Caterpillar Diesel Marine Engines: workshop manuals & fault codes PDF

Caterpillar

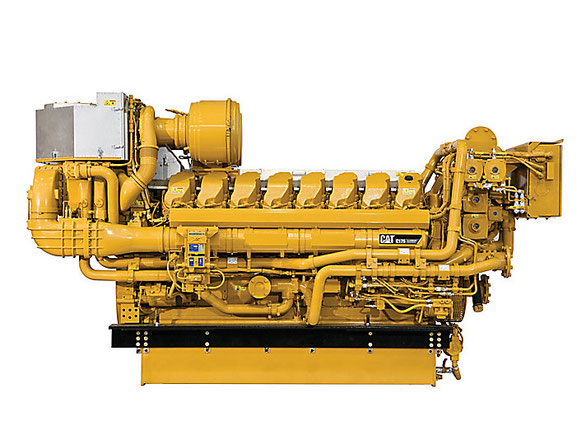

Caterpillar marine engines and equipment have proven their worth in a variety of marine environments.

For 75 years, the company has been producing ship installations (from 1020 to 16000 kW) and generator sets (from 970 kW to 4320 kW), main propulsion engines (from 93 to 7200 kW), auxiliary engines (from 162 to 5420 kW) and generators ( from 11 to 5200 kW).

The equipment serves as the main propulsion system, onboard power sources and emergency generators on pleasure boats, merchant ships and ocean-going vessels. Continuous expansion and strengthening of the material, technical and scientific and technical base allows the introduction of innovative technologies in shipbuilding.

Caterpillar equipment meets the environmental standards of the International Maritime Organization, thanks to the developed ACERT® emission, noise and smoke control technology. Reliability, ease of operation, ease of installation and maintenance are the advantages and fundamental differences of Caterpillar diesel engines from similar equipment offered on the market.

Diesel engine Caterpillar C7 ACERT

Caterpillar (USA) C7 ACERT Industrial Engine - 6-cylinder, in-line, 4-stroke, direct injection, turbocharged, air-to-air aftercooling, electronic control unit (ADEM ™ A4), HEUI ™ fuel system, enlarged block cylinders, solid steel piston.

Engine power 168-224 kW at a crankshaft speed of 1800-2200 rpm. The engine is Tier 3 (US EPA) and Stage IIIA (European Union) compliant with Advanced Combustion Emissions Reduction Technology (ACERT). It covers four systems to reduce the toxicity of exhaust gases and affects the fuel system, the combustion process, the system for introducing clean air into the engine and the introduction of electronic monitoring and control systems.

Advantages of the Caterpillar C7 ACERT diesel engine:

- Wastegate turbocharger for optimum boost.

- Reduced toxicity of combustion products.

- Lightweight design of the cylinder block.

- Adapted for installation on various industrial equipment.

- Improved connections reduce oil and coolant losses from the engine.

US Caterpillar C13 ACERT Industrial Engine - 6-cylinder, in-line, 4-stroke, direct injection, turbocharged, intercooler, electronic control unit (ADEM ™ A4), high pressure MEUI fuel system, one-piece cylinder head with channels intake and exhaust on opposite sides, solid steel piston, full sealing technology, rear power take-off from one / two shafts.

Engine power 287-388 kW at a crankshaft speed of 1800-2100 rpm. The engine meets Tier 3 (US EPA) and Stage IIIA (European Union requirements) emission standards using Advanced Combustion Emissions Reduction Technology (ACERT). It covers four systems to reduce the toxicity of exhaust gases and affects the fuel system, the combustion process, the system for introducing clean air into the engine and the introduction of electronic monitoring and control systems.

Advantages of the Caterpillar C13 ACERT diesel engine:

- The design of the gear train has been modified to increase power and reduce noise.

- The noise shield of the oil pan reduces the noise level.

- Metal multilayer cylinder head gaskets are much more reliable than conventional ones.

- A steel spacer between the two layers of spring steel increases the elasticity of the gasket.

- The elasticity of the gasket increases engine life by reducing the likelihood of gasket breakage.

- A new high-efficiency oil filter reduces engine wear and contamination.

Aje (Saturday, 04 February 2023 19:47)

Cat